120t wheat flour milling machine

Our wheat flour milling machine/plant that would cater for the need of the market various regions and countries,on the basis of their different situation.

Meanwhile,we have absorbed the advantages of other manufacturers. It is convenient to operate repair and maintain, sturdiness and durablility.

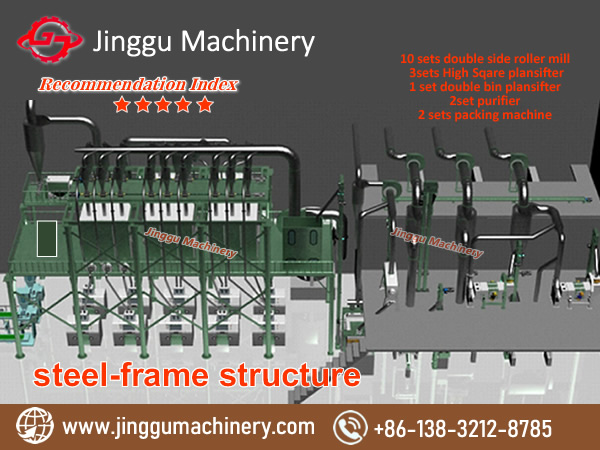

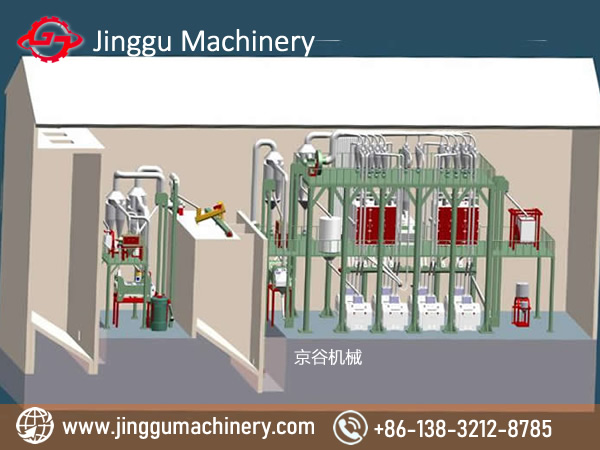

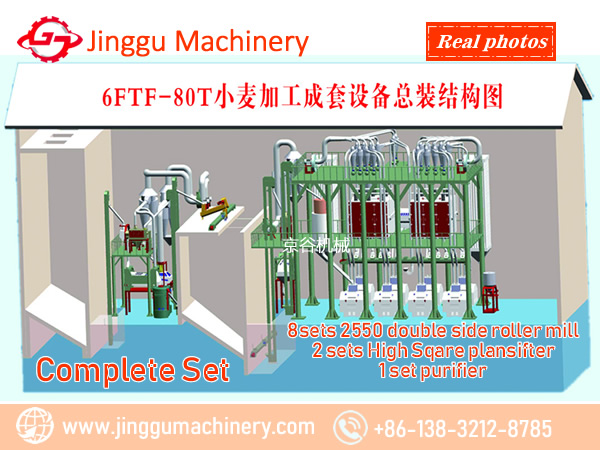

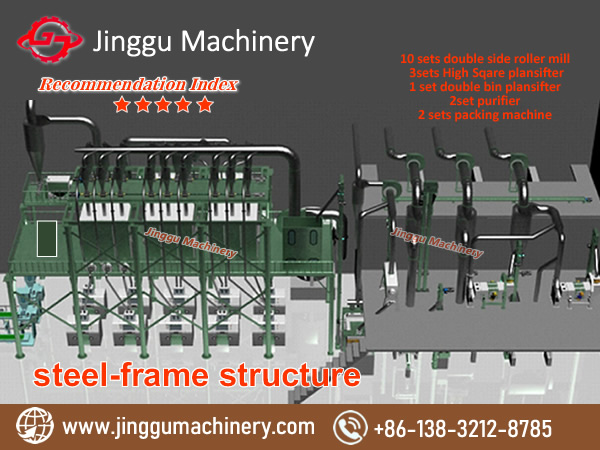

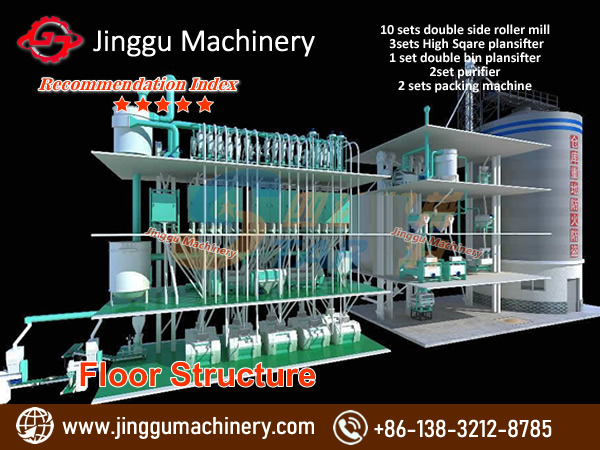

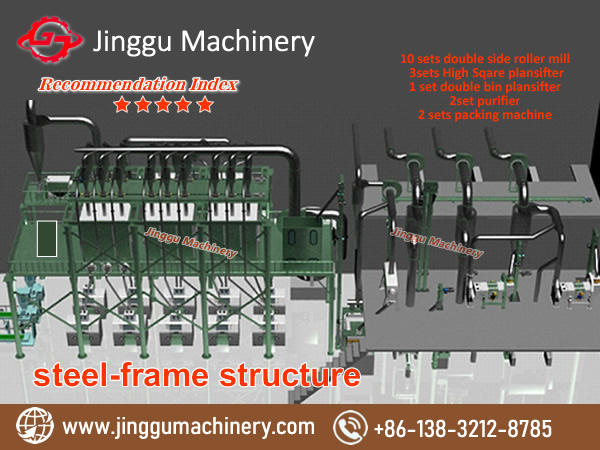

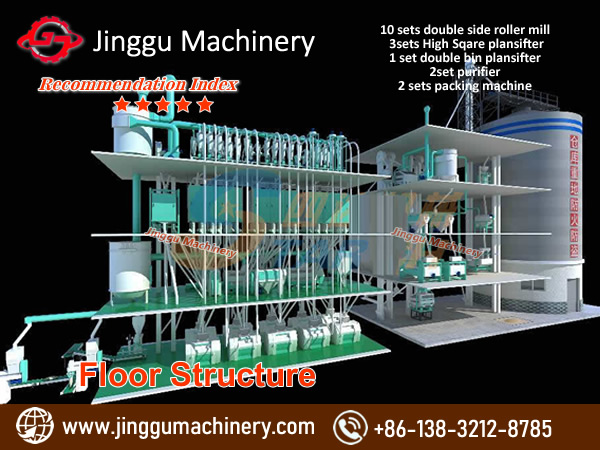

The Flour Mill Equipment of 120 tons per day compact wheat flour milling machinery are designed and installed together with the steel structure support. T

he main support structure is made of three layers:

The roller mills are located on the ground floor, the sifters are installed on the first floor;

The cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting.

Workshop height is relatively low to reduce customers' investment.

Wheat processing flow:

1. Wheat storage (silos, or warehouse) ---------- 2. Cleaning system (sifter, destoner, seprater, magnet, scourer, etc) ----------- 3. Dampening (dampener, conditioning silos, etc) ---------- 4. Milling system (roller mill, plansifter, purifier, impact detacher, etc. ) ---------- 5. Flour pressure and blending system (if need) ---------- 6. Flour packing and stacking.

Section ONE: Raw Material Cleaning Section

During this section, raw wheat/maize will be cleaned 2 or 3 times by sifter, destoner, magnetic sparator, scourer etc. Then the wheat will be cleaning enough for dampening and milling, the flour produced can be good qulaity, less bran residue, white and shinning, delicious taste

Section Two: Wheat Dampening Section

After first cleaning, Wheat need to be dampened and conditioned in silos to suitable moisture contained, then start the second cleaning before milling.

Section three: Wheat Milling section

If the wheat is dampened within several hours and with suitable moisture, they will go for second-cleaning and the start milling

Roller mill has 2 types: Frequency conversion double roller mill or Pneumatic double roller. Inside there are 2 pair roller, totally 4 rollers in each mill. Both of them are European standard, good quality, high precision and fully automatic. Using life reach 25 years.

Plansifter: Separate and screen flour according to the size difference, big sieving area and working efficiently.

Purifier: Separate fine flour grits and flour with bran grits to improve flour quality

The milling technology can be adjusted to satisfy customers' different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.