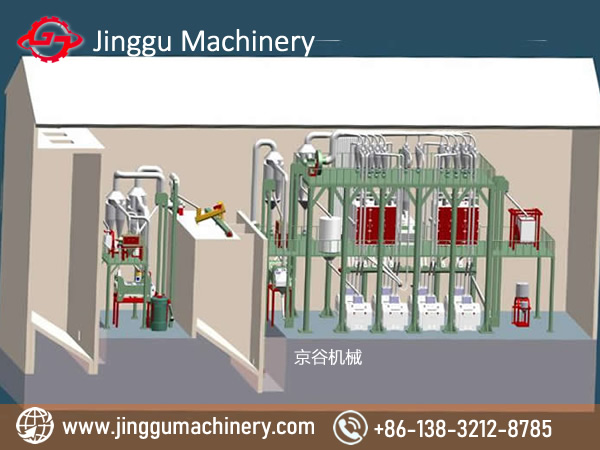

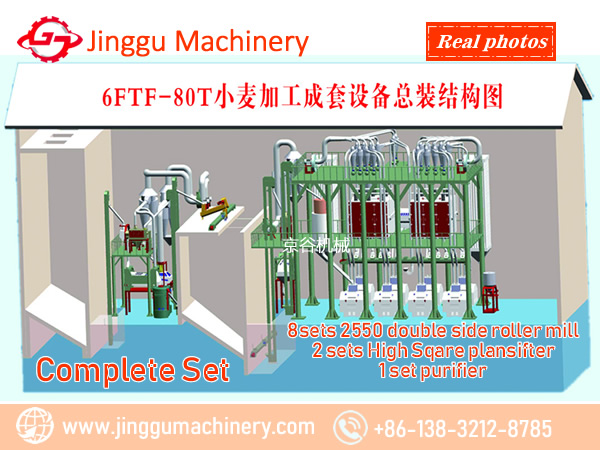

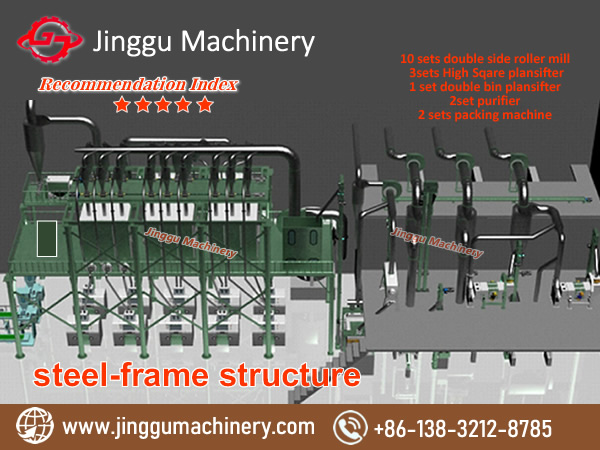

Capacity: processing 80-100t tons wheat per 24 hours.

This machine is a complete production line including cleaning, milling, packing and controlling systems.

The raw material is wheat and the final product is super fine wheat flour for making bread, cake, biscuits and so on.

When we design the whole set machine, we will think more for our client from every side. When the truck come to the factory, the truck can directly put the wheat on the Raw wheat pit, after pre-clean the raw wheat will get into the silo, no need people to carry the wheat.

Always the wheat moisture bin is construction by cement. The line is auto-working line, controlled by PLC system. Which can show all the parameters of the machine,and show the rate of the extraction, show all the machine running situation.

We would like to give some good suggest to our client, we can help them to produce different kind of flour according the local situation and our client request, like semolina,bread flour, cake flour, brown flour.

Main Equipments in Wheat Flour Milling Process

★ Cleaning: vibrating screen, rotary sieve classifier

★ Scouring: wheat scourer, wheat brusher

★ De-stone: Grading de-stoner, air-suction specific gravity stoner, air-blast specific gravity stoner

★ Magnetic separation: magnetic selector, magnetic separation plate

★ Air separation: Air separation equipments will be needed after cleaning and wheat scourer.

★ Wheat water conditioning: wheat washer, dampening

★ Milling: wheat after cleaning will go through mill machine, plan-sifter, purifier, then get the flour.